Introduction to Broach Tools

Broach tools are specialized cutting tools used in machining operations to create precision holes, slots, and intricate profiles in metal and other materials. They are widely used in industries such as automotive, aerospace, and manufacturing. These tools provide a cost-effective and highly accurate method for shaping workpieces, making them indispensable in modern machining.

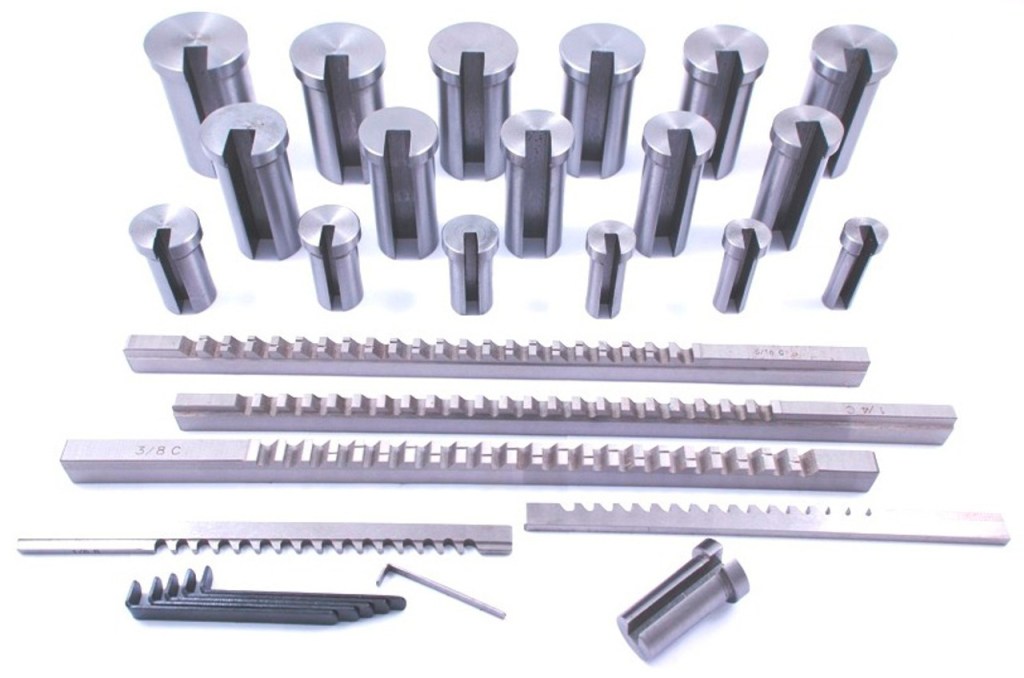

Broaching is a machining process that involves a toothed tool, known as a broach, which removes material in a controlled manner. The broach consists of multiple cutting edges arranged in a linear or rotary fashion, allowing for consistent material removal with high precision.

Types of Broach Tools

1. Surface Broach Tools

Surface broach tools are used to cut flat or contoured surfaces. These broaches can be either push or pull types, depending on the machining setup. They are commonly used for shaping complex profiles on workpieces.

2. Internal Broach Tools

Internal broach tools are designed to cut precise holes, keyways, or splines inside a workpiece. These broaches are inserted into pre-drilled holes and then pulled or pushed through the material to achieve the desired shape.

3. External Broach Tools

External broach tools are used to shape the outer surface of a workpiece. These tools are often utilized in gear manufacturing and spline cutting to create uniform external profiles.

4. Rotary Broach Tools

Rotary broach tools are used in lathes and CNC machines for creating internal and external shapes, such as hexagonal or square holes, with minimal effort. These tools rotate as they cut, reducing the need for secondary finishing processes.

5. Keyway Broach Tools

Keyway broach tools are specifically designed to cut keyways in gears, pulleys, and other machine components. They ensure precise alignment and secure fitting of parts in mechanical assemblies.

Materials Used in Broach Tools

Broach tools are typically made from high-strength materials to withstand the forces exerted during machining. Some common materials used include:

- High-Speed Steel (HSS): Offers excellent durability and sharpness for precision cutting.

- Carbide: Known for its hardness and resistance to wear, making it ideal for high-volume production.

- Powdered Metallurgy Steels: Provide enhanced strength and toughness for heavy-duty applications.

- Coated Broach Tools: Often feature coatings like TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) to extend tool life and improve performance.

Applications of Broach Tools

Broach tools play a crucial role in various industries. Some common applications include:

1. Automotive Industry

- Used for manufacturing gears, shafts, and keyways in transmission systems.

- Essential in shaping engine components with high precision.

2. Aerospace Industry

- Helps create intricate components for aircraft engines and structural parts.

- Ensures precise tolerances for enhanced performance and safety.

3. Manufacturing and Metalworking

- Used in mass production of machine components with consistent quality.

- Reduces the need for multiple machining operations, improving efficiency.

4. Medical Equipment Production

- Utilized in manufacturing surgical instruments and orthopedic implants.

- Ensures high accuracy and smooth finishes required for medical applications.

5. Defense and Firearms Industry

- Employed in the production of firearm components such as barrels and trigger mechanisms.

- Ensures precision for reliable performance and durability.

Advantages of Using Broach Tools

1. High Precision and Accuracy

Broach tools allow for extremely accurate cuts, ensuring consistent quality in production.

2. Cost-Effective Mass Production

The ability to cut complex shapes in a single pass reduces machining time and overall production costs.

3. Versatility in Design

Different types of broach tools can be customized to create various shapes and profiles, making them suitable for diverse applications.

4. Smooth Surface Finish

Broaching results in excellent surface finishes, minimizing the need for additional finishing processes.

5. Long Tool Life

Broach tools are made from durable materials, allowing for extended use with minimal wear.

Maintenance and Care of Broach Tools

To ensure the longevity and efficiency of broach tools, proper maintenance is essential. Here are some tips:

- Regular Inspection: Check for signs of wear or damage before use.

- Proper Lubrication: Use cutting fluids to reduce friction and prevent overheating.

- Storage: Store in a dry and clean environment to prevent rust and corrosion.

- Sharpening: Periodically re-sharpen to maintain cutting efficiency and accuracy.

- Correct Handling: Avoid excessive force or improper alignment during use to prevent breakage.

Choosing the Right Broach Tools

Selecting the right broach tools depends on various factors:

- Material of the Workpiece: Harder materials require carbide or coated broaches for optimal performance.

- Type of Cut Required: Determine whether an internal, external, surface, or rotary broach is needed.

- Production Volume: High-volume production may require specialized broaches with extended durability.

- Tolerance and Precision Needs: For high-precision applications, choose broaches with tight tolerances and high-quality coatings.

Conclusion

broach tools are essential components in modern machining, offering precision, efficiency, and cost-effectiveness. Whether used in the automotive, aerospace, or medical industry, these tools provide reliable performance for creating complex shapes with ease. By selecting the right type of broach tools and maintaining them properly, manufacturers can achieve high-quality results while minimizing downtime and production costs.

Understanding the various types, applications, and benefits of broach tools can help industries make informed decisions, ensuring the best outcomes in their machining processes.

Leave a comment